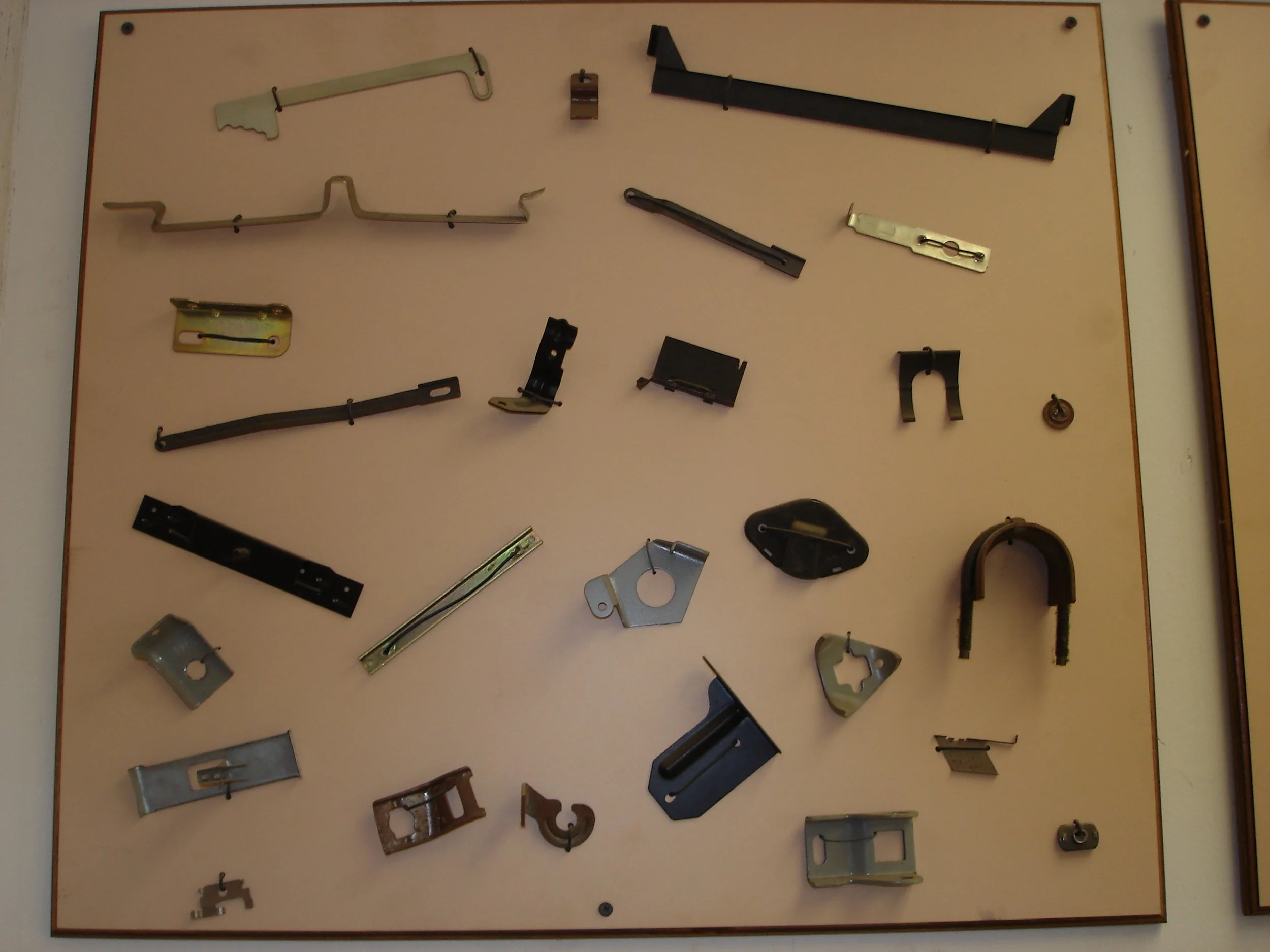

The Importance of Sourcing Parts Locally

For many industries, especially the automotive industry, sourcing parts can be a tricky, and at times, frustrating, part of the supply chain. After all, there are many considerations to balance when you're looking to source parts. For start-up companies developing products, or companies that need custom product design and custom machining, product purchasing can be even more complicated. So what kinds of things do you need to consider when you are creating, developing, and purchasing parts?

Overall, the best policy is to source products locally, and here's why:

Materials

Of course, you need to know that the materials you're using in your product come from trusted sources. The mechanical strength, among other properties, cannot be sacrificed for a better deal. You need to trust your sources. The danger of using non-locally sourced parts is that you can never be sure of the material quality of the parts that you will receive.

Craftsmanship

Do you trust the company that will create your parts for you? Have you ever had a phone call with them, or been invited to their office so that you can be positive of their legitimacy? Do you trust that they will not only use good materials, but use best practices in custom machining and custom milling to make them high-quality? When you develop a personal relationship with a CNC machining company, you are able to sit down with them and discuss which custom tooling techniques (such as waterjet cutting or wire EDM) will work best for your final product.

Language Barriers

Many larger companies choose to work with international partners across the globe to source parts for their industry. The most widely-known trade connection like this is between the United States and China. But if custom machining and custom product design is integral to the good working order and quality of your final product, you can not necessarily trust that a language barrier will not cause a problem. Larger companies have special translation and localization employees and even teams to ensure that the custom product design that they need to communicate, and collaborate on, does not get "lost in translation." But if you cannot locate an exceptionally qualified translator, you may receive a shipment and find out that it is not at all what you were looking for.

Finances

Sourcing parts locally cuts down immensely on shipping costs. In addition to being able to trust the source of your parts, you will be able to cut a better deal with a local company on your parts. Face it: there will never be a time when high-quality US-made products are cheaper than low-quality foreign made products. But you'd be surprised at the savings that sourcing custom machining parts locally can provide your business - without sacrificing quality. Furthermore, in your city, region, state, or even in the US in general - locals prefer to buy locally. You will be able to establish brand awareness, and ultimately, brand loyalty by your community.

Which brings us to our final note:

The Economy

Why, one might ask, is this a separate bullet point than finances? The answer is simple: cheap parts that seem like "good" financial choices actually contribute to corroding the economy in ways that ultimately harm your company's wealth. When you source parts locally, you increase wealth and revenue in the surrounding areas. More people are put to work locally, which results in higher tax revenue, which leads to increased prosperity both in the community and the population. On the long term, this creates more valued customers with deeper pockets for your industry. Rather than being a function of trickle-down economics, where a powerful company acquires a vast amount of wealth (often via cheap labor and sourcing), with the hopes of that spurring the economy, sourcing parts locally helps you establish a footing in the ground-up rebuilding of the American economy.

No matter what your personal financial or political belief system may be, local investment should be central to your understanding of how to fix the country's finances - and, in case you haven't noticed, the American economy has had it pretty rough in the last decade. If you don't contribute to the successes of start-ups and small and mid-sized businesses, you are effectively limiting your company's future target demographic because without domestic economic growth, there won't be anyone to buy your products. While outsourcing parts internationally may, at times, be cheaper in the very short term, the advantages of local sourcing (such as increased quality, effective communication, lower shipping times and communication, increased brand awareness and loyalty, etc.) have resounding consequences on your company's growth that will only continue to increase in importance as our economy continues to grow.